Unlocking the Power of Toyota Torque Specs: Your Guide to Proper Fastening

Are you tightening bolts on your Toyota correctly? It might seem like a minor detail, but using the correct torque specifications (torque specs) is vital for maintaining the integrity and longevity of your vehicle. Over-tightening can lead to stripped threads, broken bolts, and warped components, while under-tightening can cause parts to loosen and potentially fail, leading to dangerous situations. This comprehensive guide delves into the world of Toyota torque specs, providing you with the knowledge you need to ensure proper fastening and keep your Toyota running smoothly.

Torque specifications, often referred to as tightening torque or just torque values, are precisely engineered measurements that dictate the correct rotational force to apply to a fastener. These values are specific to each bolt and component on your Toyota, taking into account factors like material strength, thread size, and intended application. Using the correct Toyota torque settings is crucial for preventing damage and ensuring optimal performance.

While the precise origin of torque specifications is difficult to pinpoint, their importance in automotive assembly became increasingly evident with the rise of mass production. As vehicles became more complex, the need for standardized fastening procedures became paramount. Toyota, known for its commitment to quality and reliability, has always emphasized the importance of adhering to proper torque specifications in its manufacturing and service procedures.

One of the main issues related to incorrect torque application is the potential for component failure. Imagine a wheel lug nut that's been under-tightened. Over time, the vibrations and forces acting on the wheel can cause the nut to loosen further, potentially leading to the wheel detaching while driving. Conversely, over-tightening a lug nut can strip the threads or even break the stud, requiring costly repairs.

Understanding torque specs for your Toyota involves more than just finding the correct number in a manual. It requires understanding the units of measurement, typically Newton-meters (Nm) or foot-pounds (ft-lbs), and using a calibrated torque wrench to apply the precise force. This tool allows you to set the desired torque value and will click or indicate when you've reached it, preventing over- or under-tightening.

One benefit of using the correct Toyota torque specs is improved safety. Properly tightened components are less likely to fail, reducing the risk of accidents caused by loose or broken parts. Another benefit is increased component longevity. By avoiding over-tightening, you prevent stress and damage to threads and components, extending their lifespan. Finally, correct torque application contributes to optimal vehicle performance. Properly secured components function as intended, ensuring smooth operation and preventing premature wear.

Advantages and Disadvantages of Using a Torque Wrench

| Advantages | Disadvantages |

|---|---|

| Precise torque application | Initial cost of a quality torque wrench |

| Prevents over-tightening and damage | Requires proper storage and calibration |

| Ensures proper component function | Can be cumbersome in tight spaces |

Best Practices:

1. Always consult your Toyota's repair manual for the specific torque specifications for each fastener.

2. Use a calibrated torque wrench. Recalibrate your torque wrench periodically to ensure accuracy.

3. Clean the threads of both the bolt and the receiving hole before tightening.

4. Tighten bolts in a specific sequence, often outlined in the repair manual, to ensure even pressure distribution.

5. Lubricate threads as specified in the repair manual to achieve accurate torque readings.

Frequently Asked Questions:

1. Where can I find torque specs for my Toyota? Your Toyota's repair manual is the best source for specific torque specifications.

2. What is the difference between Nm and ft-lbs? Both are units of torque. Nm (Newton-meters) is the metric unit, while ft-lbs (foot-pounds) is the imperial unit.

3. Do I need a different torque wrench for different torque values? Torque wrenches have specific ranges. You'll need a wrench that covers the range of torque values you'll be working with.

4. How often should I calibrate my torque wrench? Calibration frequency depends on usage. It's generally recommended to calibrate annually or after a certain number of uses.

5. What happens if I over-tighten a bolt? Over-tightening can strip threads, break bolts, and damage components.

6. What happens if I under-tighten a bolt? Under-tightening can cause parts to loosen and potentially fail.

7. Can I use any torque wrench on my Toyota? Use a torque wrench designed for the appropriate torque range and type of fastener.

8. Are there torque specs for every bolt on my Toyota? Yes, there are specific torque specifications for almost every fastener on your vehicle.

In conclusion, understanding and applying the correct torque specifications for your Toyota is essential for maintaining its safety, reliability, and longevity. By using a calibrated torque wrench and following the manufacturer's recommendations, you can prevent costly repairs and ensure that your vehicle performs at its best. Don't underestimate the importance of this seemingly small detail. Take the time to learn the proper techniques and invest in the right tools. Your Toyota will thank you for it.

Tying a boat cleat the ultimate guide to secure docking

Unlocking opportunities your guide to jobs in the city of groveland

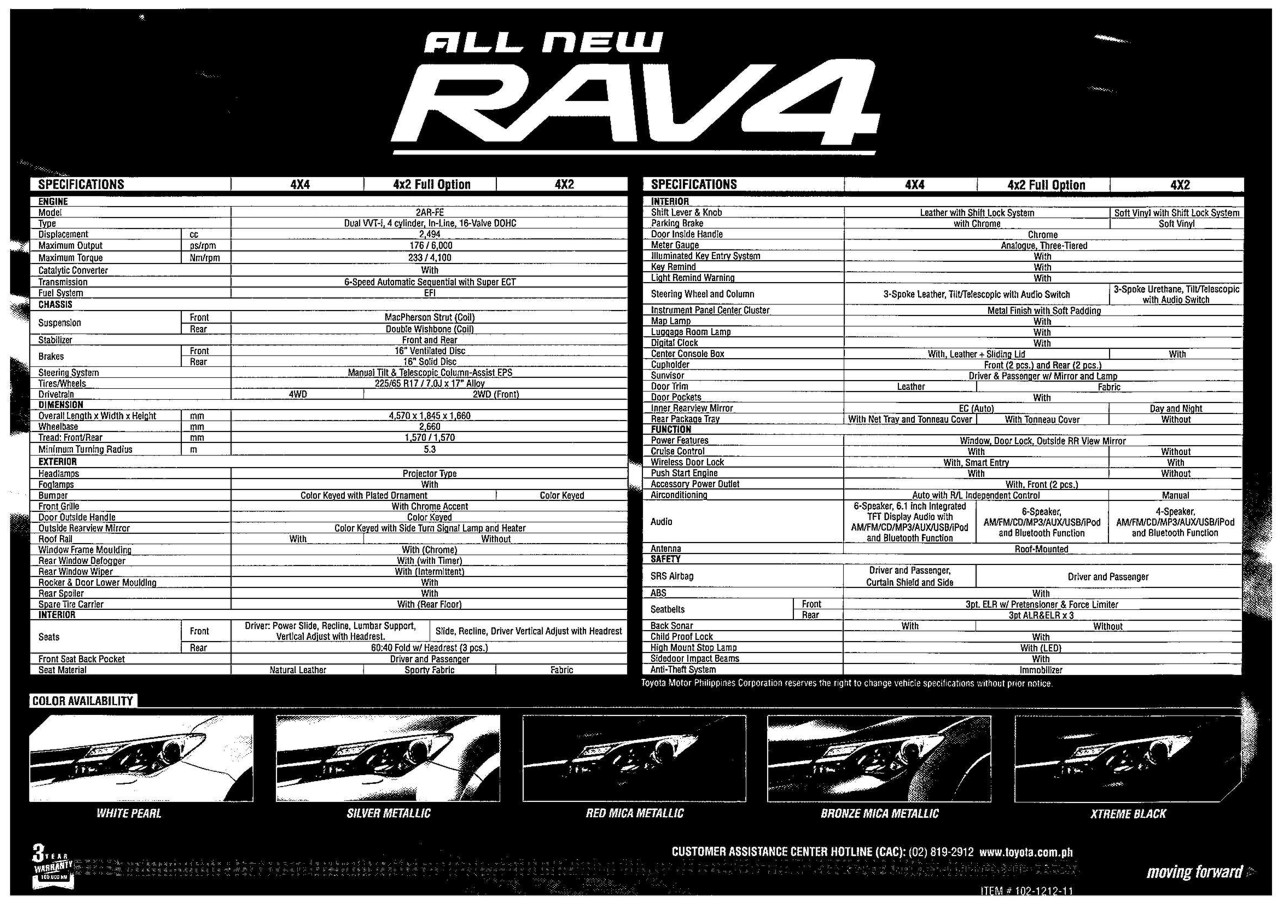

Rav4 tire pressure saga are your sensors screwing you