Understanding Your Lawn Mower's Ignition System

Is your lawn mower refusing to start? That sputtering engine might point to a problem within the ignition system, specifically the ignition coil. Understanding how this small but crucial component works can save you time, money, and frustration. This article explores the inner workings of a lawn mower's ignition coil circuit, offering insights into its diagram, troubleshooting common issues, and maintaining its optimal performance.

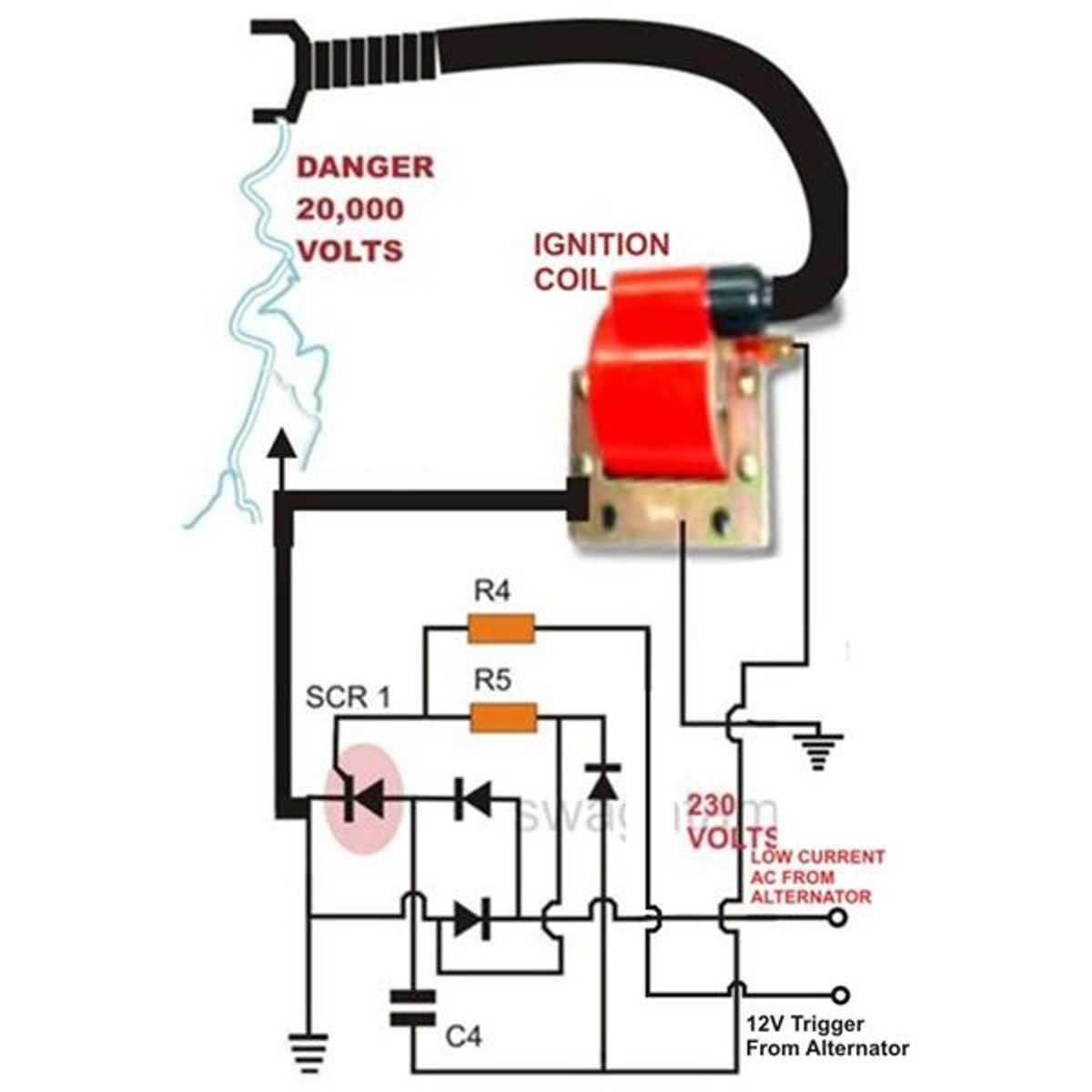

The ignition coil is the heart of your lawn mower's starting system. It's a type of transformer that takes the low voltage from the battery and converts it into the high voltage spark needed to ignite the fuel mixture in the engine's cylinder. Without a properly functioning coil, your mower won't start. Think of it as the spark of life for your lawn care routine.

A typical lawn mower ignition coil wiring schematic shows the coil connected to the engine's flywheel magneto. As the flywheel spins, the magneto generates a low-voltage current. This current flows to the primary winding of the ignition coil. The coil then amplifies this current, producing the high-voltage surge that jumps across the spark plug gap, igniting the fuel.

Tracing back in time, the principle behind the ignition coil is rooted in the discovery of electromagnetic induction. Early ignition systems were far more complex than today’s systems. The development of the small, efficient ignition coil was a significant advancement in engine technology, contributing to the widespread adoption of gasoline-powered mowers. It’s a testament to how a simple device can have a profound impact on technology.

The importance of the ignition coil cannot be overstated. A faulty ignition coil circuit diagram can lead to a variety of problems, ranging from a hard-starting engine to complete engine failure. Understanding the diagram can help you identify the source of ignition issues, saving you a trip to the repair shop. Common issues often include a broken coil wire, a corroded connection, or a faulty coil itself. Diagnosing these issues often involves testing for spark, checking the continuity of the coil's wiring, and inspecting the spark plug.

A simple test for a malfunctioning ignition coil involves checking for spark. Remove the spark plug and reconnect it to the spark plug wire. Ground the threaded part of the spark plug against the engine block and crank the engine. If you don’t see a spark, the ignition coil or other components in the ignition circuit could be faulty.

One benefit of understanding the lawn mower ignition circuit is the ability to diagnose and fix problems yourself. This can save you money on repair costs. Another benefit is improved engine performance. A healthy ignition system ensures efficient combustion, leading to smoother running and better fuel economy. Finally, regular maintenance based on understanding the ignition system can extend the life of your mower.

A practical action plan for maintaining your mower's ignition system includes regular inspections of the spark plug, spark plug wire, and the ignition coil itself. Look for signs of wear, damage, or corrosion. Ensure all connections are secure and clean. Replacing a worn spark plug annually and checking the coil wire for cracks can prevent future starting problems.

Advantages and Disadvantages of Understanding Ignition Coil Circuitry

| Advantages | Disadvantages |

|---|---|

| Self-diagnosis and repair, saving money | Risk of electric shock if not careful |

| Improved engine performance and fuel efficiency | Time investment required for learning |

| Extended lifespan of the mower | Potential for misdiagnosis and incorrect repairs |

Troubleshooting an ignition coil involves checking the wiring, connections, and the coil itself. A multimeter can be used to test the coil's resistance. Specific resistance values can usually be found in the mower's service manual. If the resistance is outside the specified range, the coil likely needs replacement.

Five common challenges related to lawn mower ignition coil circuitry include faulty wiring, corroded connections, a cracked coil, a faulty spark plug, and a malfunctioning flywheel key. Solutions typically involve replacing the faulty component or cleaning corroded connections.

FAQs: What is the function of an ignition coil? Why is my lawn mower not starting? How do I test an ignition coil? What is a flywheel magneto? How do I replace a spark plug? How often should I maintain my mower's ignition system? What are the signs of a bad ignition coil? How can I prevent ignition problems?

Tips and tricks: Always disconnect the spark plug wire before working on the ignition system. Use dielectric grease on spark plug connections to prevent corrosion. Refer to your mower's manual for specific wiring diagrams and specifications.

Understanding your lawn mower's ignition coil circuit diagram is crucial for maintaining a healthy and efficiently running machine. From troubleshooting starting problems to performing routine maintenance, this knowledge empowers you to keep your lawn looking its best. By taking the time to learn about the ignition coil and its function, you can save money on repairs, improve your mower's performance, and extend its lifespan. Taking proactive steps to maintain your lawn mower's ignition system ensures a reliable and smoothly operating machine for years to come. Remember, a well-maintained mower is a happy mower, and a happy mower means a happy lawn!

Factory units for rent near me your industrial space awaits

Unlocking serenity the essence of your boat fuel cap key

Hooked on savings your guide to discount fly fishing gear