Powering Up Your Home Choosing the Right Wire for a 200 Amp Subpanel

Ever dreamt of a workshop buzzing with power tools, a fully equipped outdoor kitchen, or a cozy guest suite with all the amenities? Adding a 200-amp subpanel can make these dreams a reality. But before you get started, there's one crucial decision: selecting the correct wire size. This seemingly small detail can make a huge difference in the safety and efficiency of your electrical system. Choosing the right wire ensures your appliances run smoothly and prevents overheating and potential fire hazards.

Determining the correct wire size for a 200-amp subpanel isn't as simple as grabbing the first roll of wire you see. It involves understanding the relationship between amperage, wire gauge, and distance. The higher the amperage, the thicker the wire needs to be to handle the electrical load safely. The distance between the main panel and the subpanel also plays a significant role, as longer runs require thicker wires to minimize voltage drop.

Historically, aluminum wiring was sometimes used for subpanels. However, due to potential issues with connections and oxidation, copper wire is now the preferred and often mandated choice for its superior conductivity and reliability. Understanding this historical context highlights the importance of choosing materials that meet current safety standards and provide long-term performance.

A 200-amp subpanel provides substantial power for a variety of applications. It allows homeowners to expand their electrical capacity without overloading the main panel. This is particularly important in older homes where the existing electrical system may not be equipped to handle the demands of modern appliances and electronics. By correctly sizing the wire for your 200-amp subpanel, you are investing in the safety and functionality of your home's electrical infrastructure.

A common misconception is that bigger wire is always better. While oversized wire won't harm your system, it is significantly more expensive and harder to work with. Choosing the correct wire size based on your specific needs is the most cost-effective and practical approach. For a 200-amp subpanel, 2/0 AWG copper wire is typically recommended for shorter runs, while longer distances may require larger gauges like 3/0 or 4/0 AWG to mitigate voltage drop.

One benefit of choosing the correct wire size is preventing overheating. Using undersized wire for a 200-amp subpanel can lead to excessive heat buildup, potentially damaging the wire insulation and creating a fire hazard. Properly sized wire ensures the safe flow of electricity, preventing this dangerous scenario.

Another advantage is maximizing appliance performance. When wires are too small for the electrical load, voltage drop can occur, reducing the efficiency of your appliances. This can lead to appliances running slower, overheating, or even failing prematurely. Choosing the right wire size ensures that your appliances receive the correct voltage for optimal performance.

Finally, correctly sizing your wire contributes to the longevity of your electrical system. Overloaded wires can degrade over time, leading to premature failure and costly repairs. By using the appropriate wire gauge, you protect your investment and ensure the long-term reliability of your electrical system.

To determine the correct wire size, consult a qualified electrician. They can assess your specific needs and recommend the appropriate wire gauge based on the distance between the main panel and the subpanel, the anticipated electrical load, and local electrical codes.

Best Practices

1. Always consult local electrical codes: Electrical codes vary by location and ensure safe installation practices.

2. Use copper wire: Copper is the preferred material for its superior conductivity and reliability.

3. Choose the right gauge: Consult an electrician to determine the correct wire gauge based on amperage and distance.

4. Use proper connectors: Ensure all connections are secure and properly insulated.

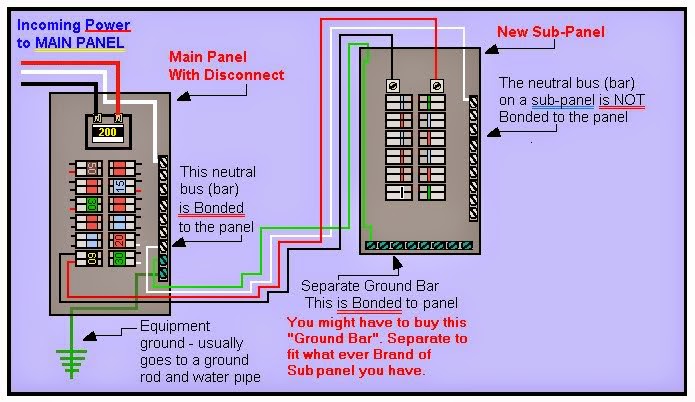

5. Ground the subpanel correctly: Proper grounding is essential for safety.Advantages and Disadvantages of Different Wire Sizes

| Wire Size | Advantages | Disadvantages |

|---|---|---|

| 2/0 AWG | Suitable for shorter runs, cost-effective | May not be suitable for longer distances |

| 3/0 AWG | Handles longer runs with minimal voltage drop | More expensive than 2/0 AWG |

FAQ:

1. What is the most common wire size for a 200 amp subpanel? 2/0 AWG is common for shorter runs.

2. Can I use aluminum wire for a 200 amp subpanel? While possible, copper is generally recommended and often required by code.

3. How do I calculate voltage drop? Online calculators and electricians can help determine voltage drop based on distance and wire size.

4. What are the signs of overloaded wiring? Overheating, dimming lights, and frequently tripped breakers can indicate overloaded wiring.

5. Why is grounding important? Grounding provides a safe path for excess electricity, preventing shocks and protecting equipment.

6. Can I install a subpanel myself? While possible, it's highly recommended to hire a qualified electrician for safe and compliant installation.

7. What is the difference between AWG and MCM? AWG is used for smaller wire sizes, while MCM (thousand circular mils) is used for larger sizes.

8. How do I size a breaker for my subpanel? A qualified electrician should size the breaker based on the load and wire size.

Selecting the correct wire size for your 200-amp subpanel is a crucial step in ensuring the safety and efficiency of your home's electrical system. While it may seem like a minor detail, the right wire size prevents overheating, maximizes appliance performance, and ensures the longevity of your electrical infrastructure. By consulting with a qualified electrician and adhering to best practices, you can confidently power up your home improvement dreams and enjoy the benefits of a robust and reliable electrical system for years to come. Remember, safety and proper installation are paramount. Investing in professional expertise ensures a properly functioning and safe electrical system, giving you peace of mind and protecting your home.

Unlocking the secrets of holley 2 barrel carburetor identification

Decoding the allure of deep green benjamin moores finest

Decoding the elk grove e tran bus schedule your ultimate guide