Mastering Pump Impeller Removal

Is your pump underperforming? Strange noises emanating from your crucial water-moving machinery? The culprit might be a damaged or clogged impeller. Knowing how to detach this vital component is key to maintaining your pump's efficiency and longevity. This comprehensive guide will walk you through the process of pump impeller removal, providing you with the knowledge and confidence to tackle this task effectively.

Removing a pump impeller might seem daunting at first, but with the right approach, it’s a manageable task. Before diving into the specifics, let’s understand why this procedure is so important. Impellers, the rotating heart of your pump, are susceptible to wear and tear, and can become clogged with debris. Regular inspection and cleaning, which often necessitates removal, can prevent costly repairs and extend the lifespan of your pump.

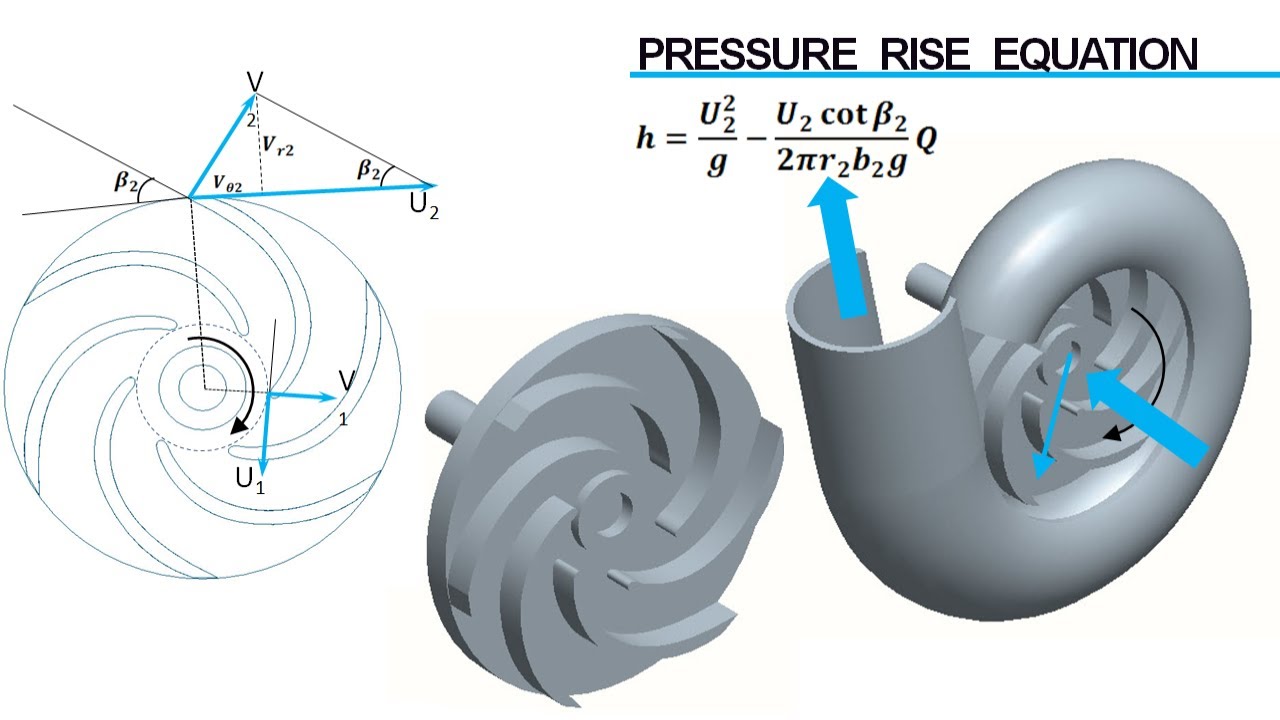

The history of pump impeller removal is intrinsically linked to the development of pumps themselves. As pump designs evolved from simple hand-operated devices to complex centrifugal and positive displacement systems, the methods for impeller detachment adapted accordingly. The fundamental principles, however, remain consistent: isolate the pump, drain the system, and carefully disassemble the necessary components to access and remove the impeller.

A crucial aspect of successfully removing a pump impeller is understanding the specific type of pump you’re working with. Different pump designs, such as centrifugal, submersible, or diaphragm pumps, have unique impeller configurations and removal procedures. For example, a centrifugal pump impeller might be secured with a key and nut, while a submersible pump impeller might require specialized tools for extraction. Identifying your pump type is the first step in ensuring you follow the correct disassembly process.

Overlooking proper procedures can lead to a host of issues, including damage to the impeller, shaft, or pump housing. Attempting to force the impeller off without the proper tools can also result in personal injury. Understanding the correct sequence of steps and utilizing the appropriate tools is paramount to a successful and safe impeller removal.

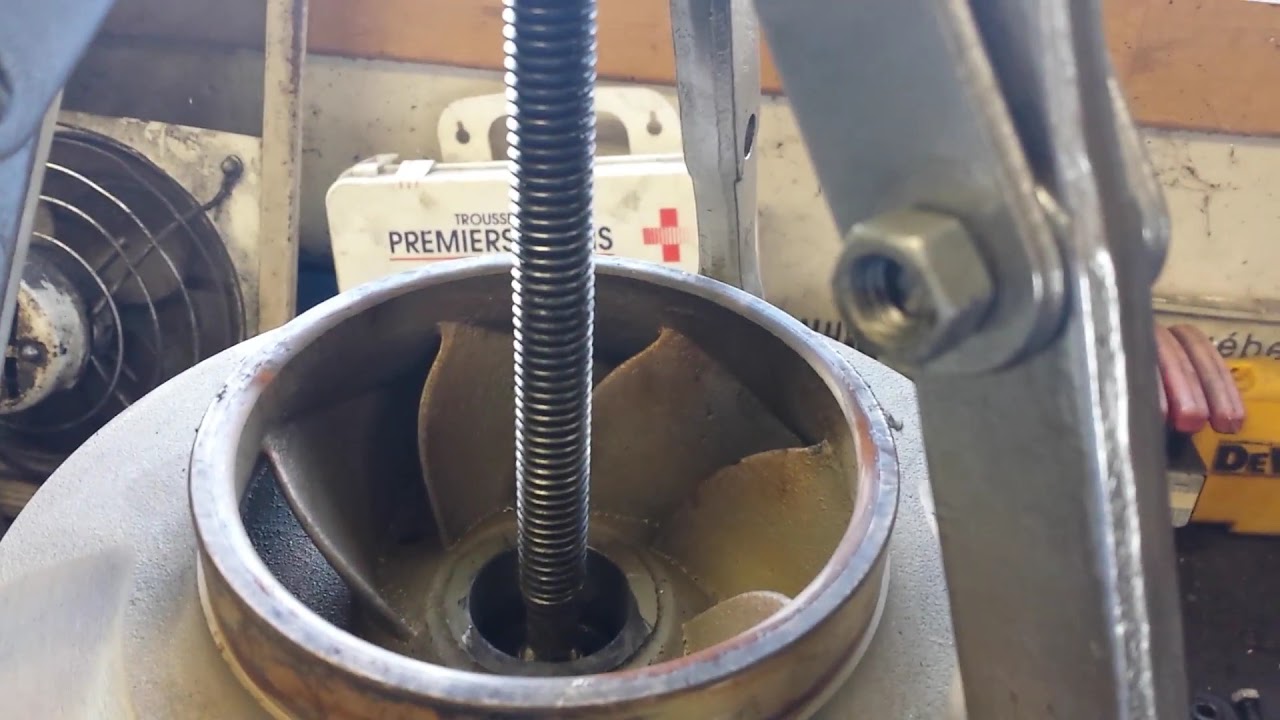

Before starting the removal process, always disconnect the power supply to the pump to prevent electrical shock. Next, drain the pump and surrounding pipework to avoid spillage. Gather the necessary tools, which may include wrenches, screwdrivers, pliers, and possibly specialized impeller pullers, depending on your pump model. Refer to your pump's manual for specific instructions and safety precautions.

Three key benefits of learning how to remove a pump impeller include: preventing costly repairs by addressing minor issues early, extending the pump's lifespan through regular maintenance, and increasing your self-sufficiency by handling repairs yourself. For example, removing the impeller allows you to clear clogs that could eventually lead to motor burnout, a significantly more expensive repair.

Step-by-Step Impeller Removal Guide:

1. Disconnect Power and Drain System.

2. Remove Pump Casing.

3. Detach Impeller Assembly.

4. Inspect and Clean Impeller.

Advantages and Disadvantages of Removing a Pump Impeller

| Advantages | Disadvantages |

|---|---|

| Prevent costly repairs | Potential for damage if not done correctly |

| Extend pump lifespan | Requires specialized tools for some pumps |

| Increased self-sufficiency | Can be time-consuming |

Five Best Practices:

1. Always consult your pump's manual.

2. Use the correct tools.

3. Exercise caution when working with electrical components.

4. Inspect the impeller for damage after removal.

5. Lubricate the impeller shaft before reassembly.

FAQs

1. Q: Why is my pump not delivering water? A: A clogged or damaged impeller could be the reason.

2. Q: How often should I remove and inspect my impeller? A: Refer to your pump’s manual for recommended maintenance intervals.

3. Q: What tools do I need to remove a pump impeller? A: This varies depending on the pump type; consult your manual.

4. Q: Can I remove an impeller without draining the pump? A: No, draining the pump is essential to avoid spillage and potential damage.

5. Q: How do I know if my impeller is damaged? A: Look for cracks, chips, or excessive wear.

6. Q: What should I do if I can’t remove the impeller? A: Consult a qualified pump technician.

7. Q: Is it difficult to remove a pump impeller? A: With the right tools and guidance, it’s a manageable task.

8. Q: Where can I find more information about my specific pump model? A: The manufacturer’s website or manual is the best resource.

In conclusion, understanding the process of pump impeller removal is a valuable skill for any pump owner. From preventing costly repairs and extending the life of your pump, to gaining self-sufficiency in maintaining your equipment, the benefits are substantial. By following the correct procedures, using the right tools, and exercising caution, you can successfully remove, inspect, and clean your pump impeller, ensuring efficient and reliable operation for years to come. Don't hesitate to consult your pump's manual or seek professional help if you encounter any difficulties. Investing time in learning this essential maintenance task will ultimately save you time, money, and frustration in the long run. Take the initiative today and master the art of pump impeller removal – your pump will thank you for it.

Dark green color combinations unleash your inner design guru

Streaming the outsider exploring hbos gripping crime drama

Finding hope and strength gods promises and expectations