Mastering PT Cruiser Torque Specs: Your Comprehensive Guide

Are you working on your PT Cruiser and unsure about the correct torque specifications? Tightening bolts and nuts to the right torque is crucial for maintaining the integrity of your vehicle and preventing costly repairs down the road. Whether you’re a seasoned mechanic or a DIY enthusiast, understanding PT Cruiser torque specs is essential for a successful project.

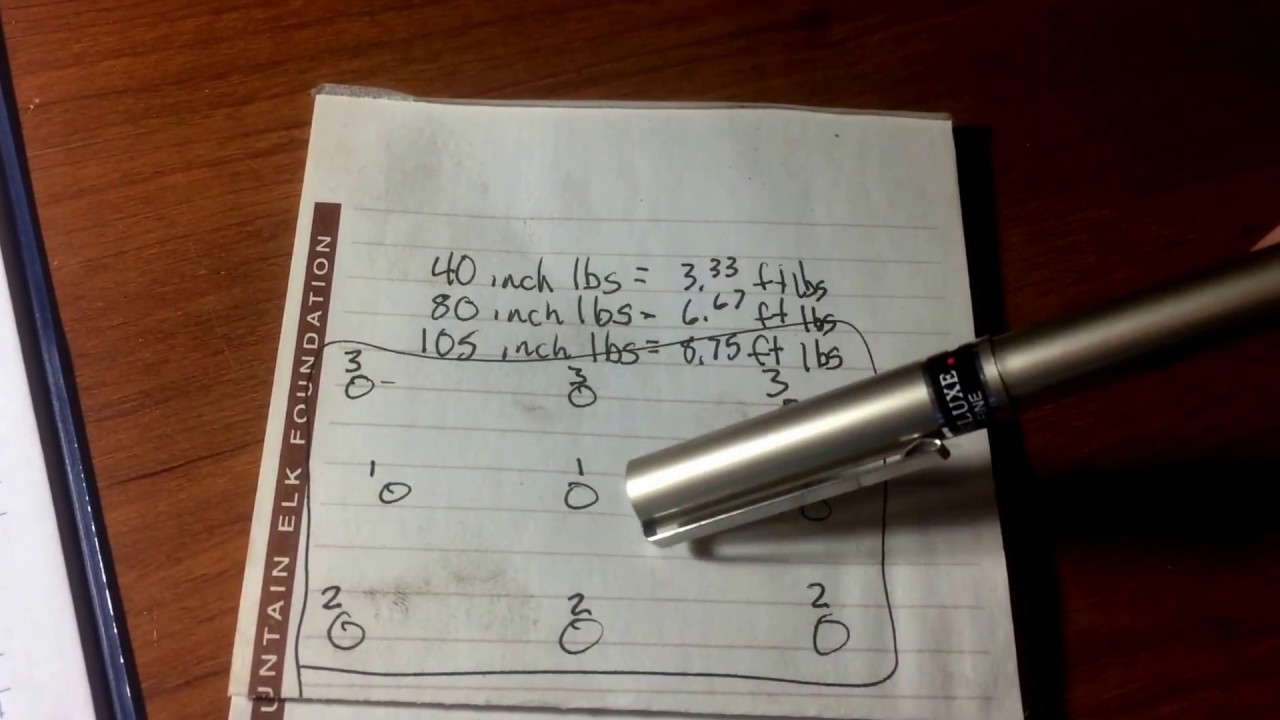

This comprehensive guide dives deep into the world of PT Cruiser torque specs, covering everything from cylinder head bolts to wheel lug nuts. We'll explore the importance of using the correct tightening values, discuss common issues that arise from improper torquing, and provide you with the knowledge you need to confidently tackle your next PT Cruiser repair or maintenance task.

Ignoring proper torque specifications can lead to a variety of problems, ranging from stripped threads and broken bolts to warped components and even engine damage. Over-tightening can cause stress fractures, while under-tightening can lead to parts loosening and potentially falling off. Using the correct PT Cruiser torque values is a simple yet crucial step in ensuring the longevity and reliability of your vehicle.

While a general torque chart can provide a starting point, consulting a PT Cruiser-specific repair manual is highly recommended. These manuals contain detailed torque specifications for every component, ensuring you're using the precise values for your specific model year and engine type. Remember, variations can exist between different PT Cruiser models, so always double-check the correct information for your vehicle.

Beyond just knowing the numbers, understanding the proper techniques for applying torque is equally important. This includes using a calibrated torque wrench and following the correct tightening sequence, which often involves a multi-stage process of gradually increasing the torque in specific increments. We’ll delve into these best practices later in this guide.

The PT Cruiser, manufactured by Chrysler from 2000 to 2010, gained popularity for its retro styling. Maintaining its mechanical integrity requires adhering to proper torque specifications. These specifications, developed by Chrysler engineers, ensure that fasteners are tightened with the optimal force, preventing damage and ensuring proper function.

A crucial aspect of PT Cruiser maintenance is understanding the cylinder head bolt torque sequence and specifications. Incorrect tightening can lead to warped heads or blown head gaskets, requiring costly repairs. Similarly, wheel lug nut torque is essential for safety, preventing wheel detachment while driving.

For example, the PT Cruiser's 2.4L engine typically requires a specific torque sequence and final torque value for its head bolts. This process might involve tightening the bolts in several stages, starting with a lower torque and gradually increasing to the final specified value. A repair manual will outline this procedure precisely.

One benefit of adhering to the correct PT Cruiser torque specs is preventing damage to threaded components. Over-tightening can strip threads, making it impossible to secure the fastener properly. Another advantage is ensuring even pressure distribution on gaskets, preventing leaks and ensuring a proper seal. Finally, correct torquing contributes to the overall longevity of the vehicle by preventing premature wear and tear on components.

Always refer to a reliable PT Cruiser repair manual for specific torque values. Use a calibrated torque wrench and follow the recommended tightening sequence. Clean and lubricate threads before tightening fasteners.

Advantages and Disadvantages of Using Correct Torque Specs

| Advantages | Disadvantages |

|---|---|

| Prevents damage to components | Requires a torque wrench and proper technique |

| Ensures proper function and reliability | Time-consuming compared to simply tightening |

| Enhances safety |

Best Practices:

1. Use a calibrated torque wrench.

2. Consult a PT Cruiser-specific repair manual.

3. Clean and lubricate threads.

4. Follow the specified tightening sequence.

5. Double-check your work.

FAQ:

1. What is torque? Torque is a rotational force.

2. Why is torque important? Correct torque prevents damage.

3. Where can I find PT Cruiser torque specs? In a repair manual.

4. What type of torque wrench should I use? A calibrated click-type torque wrench.

5. What is a torque sequence? A specific order for tightening bolts.

6. Can I use a regular wrench? No, use a torque wrench.

7. What happens if I over-tighten? You can strip threads or break bolts.

8. What happens if I under-tighten? Parts can loosen and fall off.

Tips and Tricks: Mark bolts after tightening to easily identify any that have loosened. Periodically check important fasteners for proper torque.

In conclusion, understanding and applying the correct PT Cruiser torque specifications is fundamental for anyone working on this vehicle. From preventing stripped threads and broken bolts to ensuring the proper function and longevity of critical components, the importance of correct torque cannot be overstated. While accessing a reliable PT Cruiser-specific repair manual is crucial for obtaining the precise torque values for your specific model, this guide has provided a foundational understanding of the principles and best practices involved. By investing in a quality torque wrench, following the recommended tightening sequences, and adhering to the tips and tricks outlined above, you can significantly reduce the risk of costly repairs and ensure the continued reliable performance of your PT Cruiser. Take the time to do the job right, and your PT Cruiser will thank you for it. Remember, a little precision goes a long way in maintaining the health and longevity of your vehicle. Don't underestimate the importance of these seemingly small details – they can make a world of difference.

Decoding the ice cream haircut meme phenomenon

Conquering fear with faith stickers a powerful symbol

Unlocking your magical legacy exploring the inheritance of magic