Mastering Grade 8 Bolt Torque Specifications

Are your bolted connections as strong as they could be? The integrity of any structure, machine, or vehicle relies heavily on the proper fastening of its components. This is where understanding Grade 8 bolt torque specifications becomes paramount. Ignoring these specifications can lead to disastrous consequences, from loose joints and vibrations to catastrophic failures. This article delves into the world of Grade 8 bolt torque, providing a comprehensive guide to ensure your bolted connections are secure and dependable.

Grade 8 bolts represent a high-strength fastener option, widely used in demanding applications where robust connections are essential. These bolts are made from medium carbon alloy steel, quenched and tempered for enhanced strength and durability. Their superior tensile strength and yield strength make them ideal for heavy-duty machinery, automotive applications, and structural steelwork. However, realizing their full potential hinges on applying the correct tightening techniques and adhering to the recommended Grade 8 bolt torque values.

The history of standardized bolt torque specifications is intertwined with the development of industrial manufacturing and the increasing need for reliable and predictable assembly processes. As engineering designs became more complex and the demands on bolted connections increased, the need for standardized torque values became evident. This led to the development of various standards organizations, such as the Society of Automotive Engineers (SAE) and the International Organization for Standardization (ISO), which define specific torque recommendations for different bolt grades and sizes.

The importance of adhering to Grade 8 bolt torque specifications cannot be overstated. Incorrect tightening can result in a number of issues. Under-tightening can lead to joint separation, loosening under vibration, and ultimately, failure. Over-tightening, on the other hand, can cause bolt yielding, stripping of threads, or even bolt fracture. Proper tightening, guided by the recommended torque specifications, ensures the optimal clamping force, preventing these potential problems and guaranteeing the long-term integrity of the bolted connection.

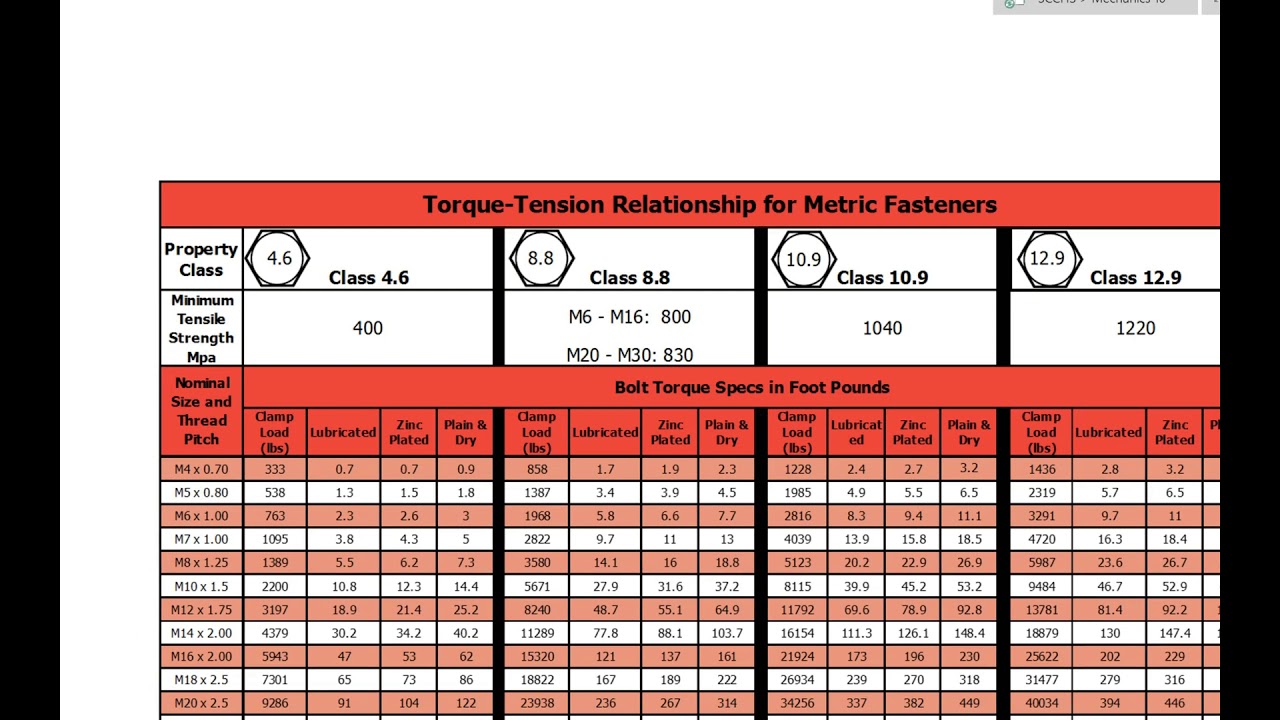

Understanding the factors influencing Grade 8 bolt torque is crucial. Lubrication plays a significant role. A lubricated fastener requires less torque to achieve the desired clamping force compared to a dry fastener. The type of lubricant also matters, as different lubricants offer varying friction coefficients. Thread condition also affects torque requirements. Damaged or dirty threads can lead to inaccurate torque readings and compromised joint integrity. Therefore, clean and properly formed threads are essential for achieving accurate and reliable tightening.

One benefit of adhering to proper Grade 8 bolt torquing is increased safety. Secure connections prevent equipment failure and potential accidents. Another benefit is enhanced reliability. Correctly torqued bolts maintain their clamping force over time, reducing the risk of loosening and ensuring long-term performance. Finally, proper torquing improves efficiency. By preventing failures and rework, correct torquing minimizes downtime and maintenance costs.

Developing an action plan for implementing proper Grade 8 bolt torquing involves several steps: selecting the appropriate torque wrench, consulting the relevant torque specification charts, preparing the bolt and nut surfaces, and applying the torque in a controlled and consistent manner. Successful examples include automotive assembly lines where precise torque control is critical for safety and performance.

Advantages and Disadvantages of Specific Torque Values

| Advantages | Disadvantages |

|---|---|

| Consistent clamping force | Requires specific tools and training |

| Improved joint reliability | Can be time-consuming |

| Reduced risk of failure | Sensitive to lubrication and thread condition |

Best practices include using calibrated torque wrenches, lubricating fasteners appropriately, and following a consistent tightening sequence. Real-world examples include bridge construction, where precise torque control is essential for structural integrity.

Challenges in implementing torque specifications include variations in thread conditions and lubricant effectiveness. Solutions involve careful surface preparation and using consistent lubrication practices.

FAQs often address topics such as the difference between dry and lubricated torque values, the impact of thread pitch on torque, and the selection of appropriate torque wrenches.

Tips and tricks include using a torque angle gauge for increased accuracy and regularly calibrating torque wrenches.

In conclusion, understanding and applying Grade 8 bolt torque specifications is essential for creating strong, reliable, and safe bolted connections. By following best practices, utilizing the right tools, and understanding the factors that influence torque, you can ensure the long-term integrity of your assemblies. From preventing catastrophic failures to minimizing maintenance costs, the benefits of proper bolt torquing are undeniable. Take the time to familiarize yourself with the relevant torque specifications and implement a consistent tightening process. Investing in proper torquing practices is an investment in safety, reliability, and efficiency. This knowledge empowers you to build and maintain structures and equipment with confidence, knowing that your bolted connections are secure and dependable for years to come. Don't underestimate the power of a properly tightened bolt – it's the foundation of a robust and reliable assembly.

English channel behr paint color a deep dive

Conquer the nba playoffs bracket challenge

Indiana public access secrets revealed