Decoding the Magnetic Contactor Coil Symbol: Powering Industrial Control

In the intricate world of industrial automation and electrical control systems, a small, unassuming symbol holds immense power: the magnetic contactor coil symbol. This seemingly simple representation on wiring diagrams signifies a crucial component responsible for controlling high-voltage circuits and enabling automated operations.

Imagine a factory floor teeming with machinery. The smooth, synchronized movements of robotic arms, the rhythmic hum of conveyor belts, and the precise operation of complex equipment are all orchestrated by a network of electrical signals. At the heart of this control system lies the magnetic contactor, and its coil, represented by its distinct symbol, acts as the gatekeeper for the flow of power.

Understanding the magnetic contactor coil symbol is fundamental for anyone working with electrical diagrams and control systems. It unlocks the ability to interpret circuit functionality, troubleshoot issues, and design efficient automation processes. From simple motor starters to complex industrial control panels, the magnetic contactor coil symbol is ubiquitous, serving as a visual shorthand for a crucial component.

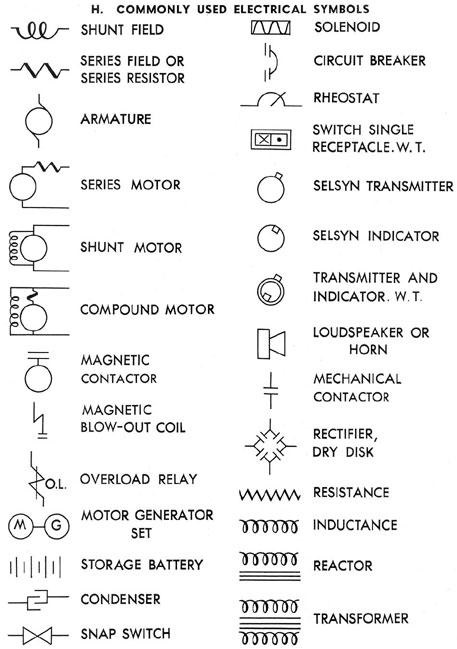

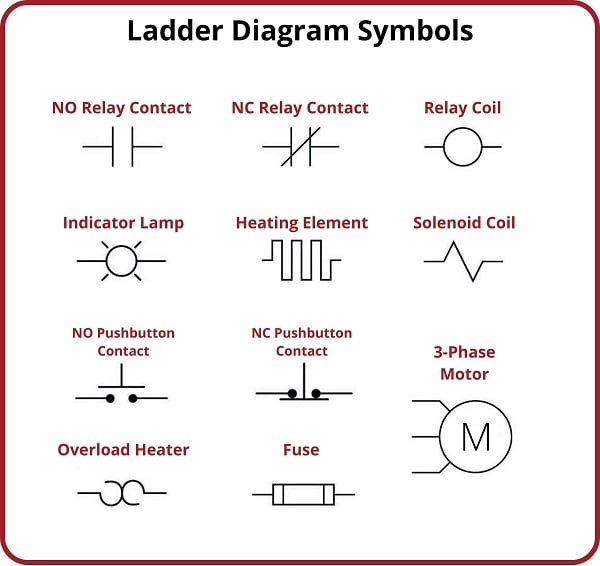

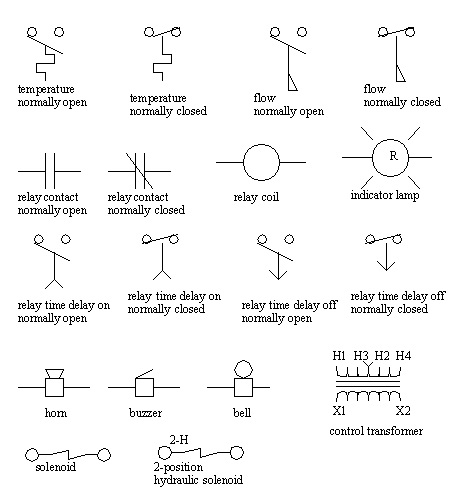

The notation for the magnetic contactor coil can vary slightly depending on the specific standard used, but generally involves a circle or oval representing the coil itself, often with terminals depicted for connection to the control circuit. Variations may include labels indicating the coil voltage or other relevant parameters.

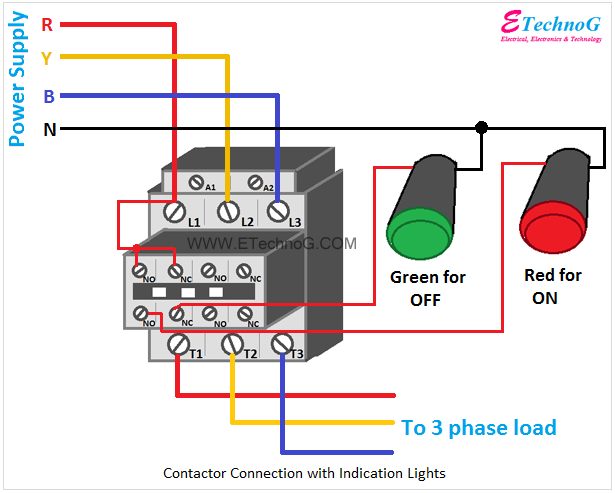

This symbol’s significance lies in its representation of the electromagnetic principle that governs the contactor's operation. When an electrical current is applied to the coil, it generates a magnetic field that attracts a movable armature. This armature, in turn, closes a set of contacts, allowing power to flow to the connected load – be it a motor, a pump, or another piece of industrial equipment.

Historically, contactors were manually operated, requiring physical intervention to switch circuits. The advent of electromagnetic contactors, and the development of standardized symbols to represent them, revolutionized industrial control, enabling remote and automated operation of electrical systems. This shift laid the groundwork for modern automation and contributed significantly to increased efficiency and safety in industrial environments.

One common issue related to magnetic contactor coils is coil burnout due to overheating. This can occur due to excessive voltage, prolonged energization, or faulty wiring. Troubleshooting these issues requires understanding the coil's specifications, examining the wiring diagram, and using appropriate testing equipment.

A key benefit of utilizing magnetic contactors and understanding their associated symbolism is remote control. The low-voltage control circuit allows operators to control high-power loads from a safe distance.

Another advantage is automation. Contactors can be integrated into automated systems using programmable logic controllers (PLCs) and other control devices, allowing for complex sequences and timed operations.

Safety is paramount. Magnetic contactors provide a safe and reliable method for switching high-power circuits, protecting personnel and equipment from electrical hazards.

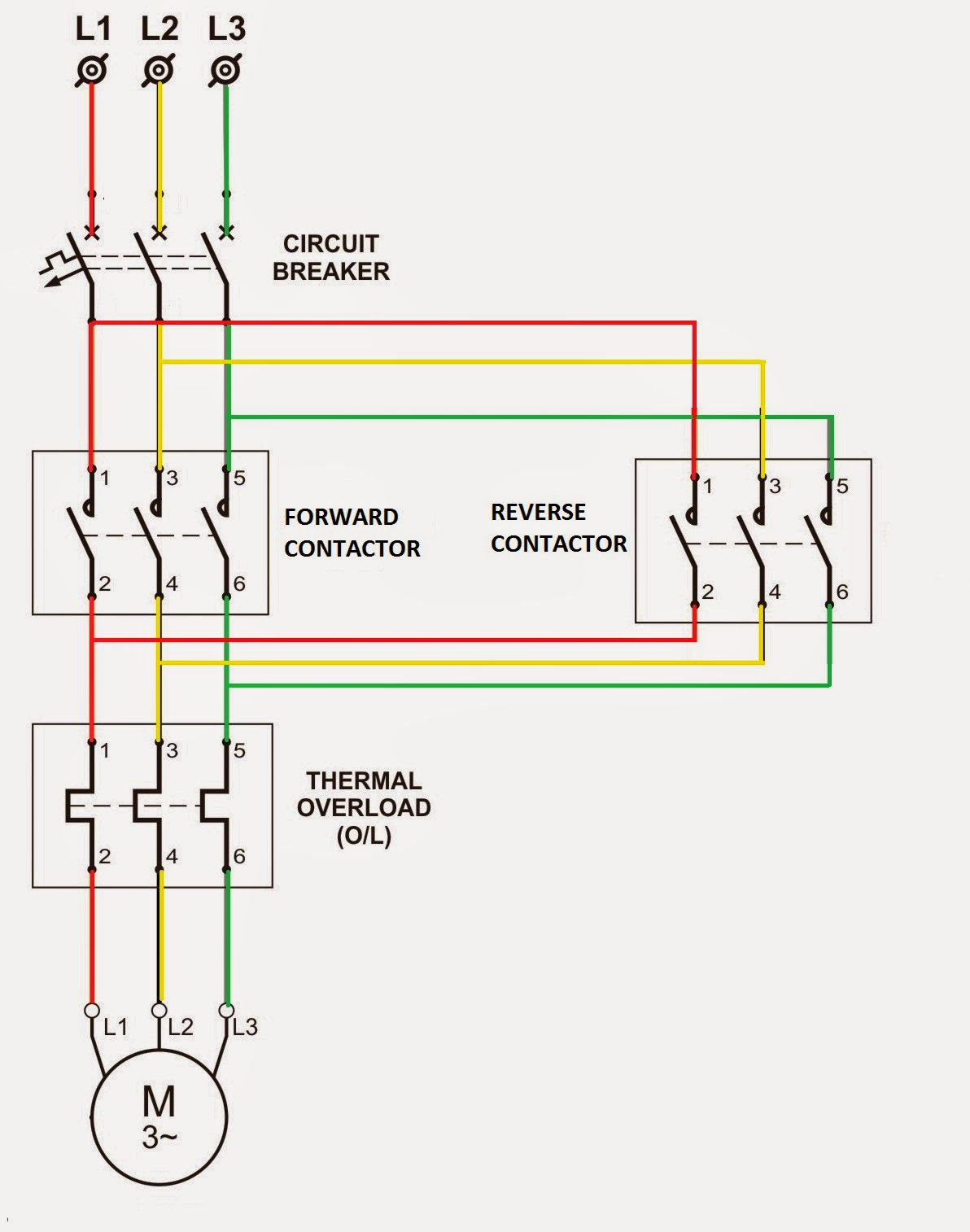

A simple example is a motor starter circuit, where a magnetic contactor is used to control a three-phase motor. The coil is energized by a start button, closing the contactor's contacts and starting the motor.

Advantages and Disadvantages of Magnetic Contactor Coil Systems

| Advantages | Disadvantages |

|---|---|

| Remote Control | Potential for Coil Burnout |

| Automation Capabilities | Can be Noisy During Operation |

| Enhanced Safety | Requires Regular Maintenance |

Best practices include proper sizing of the contactor for the load, ensuring correct wiring according to the diagram, and regular inspection for wear and tear.

Real-world examples include controlling pumps in water treatment plants, managing conveyors in manufacturing facilities, and operating lighting systems in large buildings.

Frequently asked questions include: What voltage should the coil be? How do I troubleshoot a faulty coil? What are the different types of contactor coils? etc.

Tips and tricks: Always consult the manufacturer's datasheet for specific coil specifications. Use appropriate safety precautions when working with electrical circuits. Regularly inspect and clean contacts to ensure reliable operation.

In conclusion, the magnetic contactor coil symbol, a seemingly small element in electrical diagrams, represents a critical component that underpins industrial automation and control systems. Its ability to control high-power circuits remotely and safely has revolutionized industrial processes, enhancing efficiency and protecting personnel. Understanding this symbol and the underlying principles of magnetic contactors is essential for anyone working with electrical systems, enabling informed decision-making, efficient troubleshooting, and the design of robust and reliable automation solutions. By mastering the intricacies of this symbol, we can harness the power of magnetic contactors to drive innovation and progress in the industrial landscape. Explore further by researching electrical control systems and automation principles. Investigate different contactor manufacturers and their product offerings to deepen your understanding of this important component.

Tucker carlson biography book sales analysis

Unlocking strikes your guide to solid reactive bowling balls

Exploring the world of brave new world manga adaptations